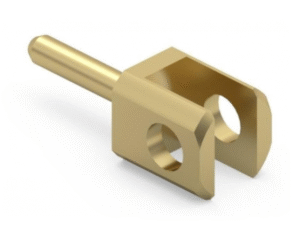

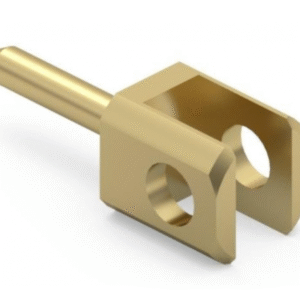

Metal Joint Parts for Electric Wire

– Precision Machined Brass & Alloy Connectors

Metal Joint Parts for Electric Wire are high-precision mechanical connectors designed to provide secure linkage, alignment, and load transfer in electrical wiring systems and related mechanical assemblies. These components are widely used in electric wire connections, cable routing systems, control mechanisms, and light industrial equipment where strength, reliability, and dimensional accuracy are critical.

Featuring multiple joint styles such as clevis joints, eye joints, threaded connectors, and end fittings, these parts are engineered to ensure stable mechanical performance while supporting smooth movement or fixed positioning in electrical and electromechanical applications.

Material & Manufacturing Process

These metal joint parts are typically manufactured from brass, aluminum alloy, stainless steel, or customized metal alloys, offering an ideal balance of strength, corrosion resistance, and machinability. Brass versions are especially popular for electrical applications due to their excellent conductivity and oxidation resistance.

Key machining and processing methods include:

CNC Turning & Milling for high-precision geometry

Automatic Lathe Machining for consistent mass production

Drilling & Tapping for accurate pin holes and threaded sections

Fork Slot Milling / Clevis Machining for joint articulation

Chamfering & Deburring to ensure smooth edges and safe handling

Surface Finishing such as polishing, sandblasting, or anodizing (optional)

Each part is produced under strict dimensional control to ensure compatibility and interchangeability.

Features & Advantages

High mechanical strength for stable wire and joint connections

Precision-machined tolerances for smooth assembly and operation

Excellent corrosion resistance, ideal for long-term use

Multiple joint configurations to suit different installation needs

Suitable for electrical and mechanical integration

Applications

Electric wire and cable connection systems

Electrical equipment and control assemblies

Automation and motion control components

Industrial machinery and hardware fittings

Custom electromechanical linkage systems

OEM / ODM Precision Metal Parts Manufacturer

As an experienced OEM/ODM manufacturer of precision metal joint parts, we provide end-to-end manufacturing services from design optimization to mass production. Whether you require customized dimensions, specific materials, surface treatments, or branded packaging, our CNC machining capabilities ensure consistent quality and scalable output.

We support prototype development, small-batch orders, and high-volume production for global customers across electrical, industrial, and automation markets.

If you are sourcing a “Metal Joint Parts for Electric Wire”, we offer reliable, precision-engineered solutions tailored to your market. Contact us now for OEM customization, samples, or bulk quotations.

Reviews

There are no reviews yet.