ISO9001& IATF16949 certified factory

Product design

Mechanical drawing

Quick quote

Quick sample

CNC machining

Forging Processing

Precision casting

Sheet Metal Processing

Electrolytic polishing

Passivation treatment

Electroplating

Spraying

Anodizing

Laser engraving

Inspection

Assembly

Packaging

FOB Service

CIF Service

Grancen Pte Ltd is headquartered in Singapore and is backed by a team with over 20 years of experience in the manufacturing of industrial metal components. Our founder and his team are deeply passionate about metal part manufacturing. While we are a relatively young company compared to the long history of industrial manufacturing, we are confident in our ability to deliver high-quality components that serve a growing range of applications.

We believe that our relationship with customers is like that between a bolt and a nut—closely connected and mutually supportive. We always place customer service and product quality as our top priorities, even amidst fluctuating international tariffs and increasing cost pressures.

What services do Grancen offer?

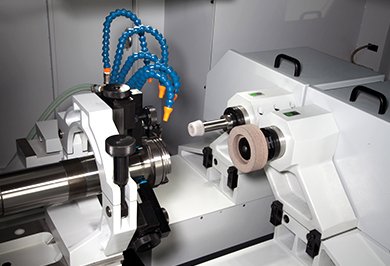

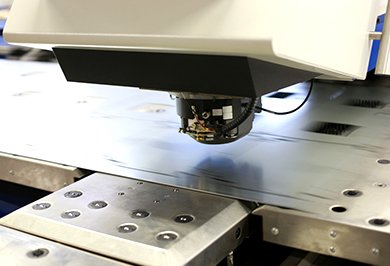

CNC Machining

High-precision processing, complex shape processing, efficient production, flexibility and repeatability, Human error reduction, and data management and optimization.

Forging Processing

Produce various high-strength and high-precision components, such as bolts, nuts, pins, rivets, shaft sleeves, step shafts, and other fasteners or links.

Sheet Metal Processing

It is widely used in the production of various metal components, components and products, such as chassis, mechanical structures, electronic equipment casings, etc.

Precision Casting

High precision, complex shape and structural casting, excellent surface quality, high production efficiency, and precise molding in metal processing

Our Products

From Prototype to Production

Our team of engineering and manufacturing experts have experience creating products for a wide variety of industries

How to Work With Us

Upload a CAD File

To start, simply select a manufacturing process and upload a 2D and 3D CAD file.

Get Quote with Message

Within a few hours we'll send you design for manufacturability analysis and real-time pricing.

Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts in as fast

Grancen operates three manufacturing facilities globally—in Singapore, Johor (Malaysia), and Sichuan (China). Equipped with high-precision CNC machines and inspection equipment from Switzerland, Germany, the United States, and Japan, we manufacture precision components for clients around the world. The close coordination among our factories enables us to serve global clients efficiently and reliably.

We are proud to work with distributors and customers in over 40 countries across a wide range of industries. Looking ahead, we remain committed to providing higher-quality and more cost-effective metal components through our professional approach and continuous dedication.

- 555856,First Centre #02-09 Singapore

- 84300,Muar, Johor, Malaysia

- 629000,Suining City,Sichuan Province, P.R. China