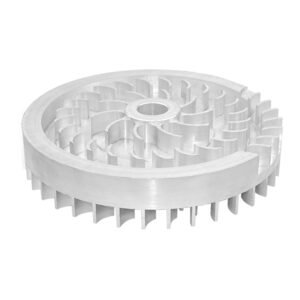

CNC Machined Aluminum Flywheel

Lightweight High-Performance Rotational Energy Storage Solution

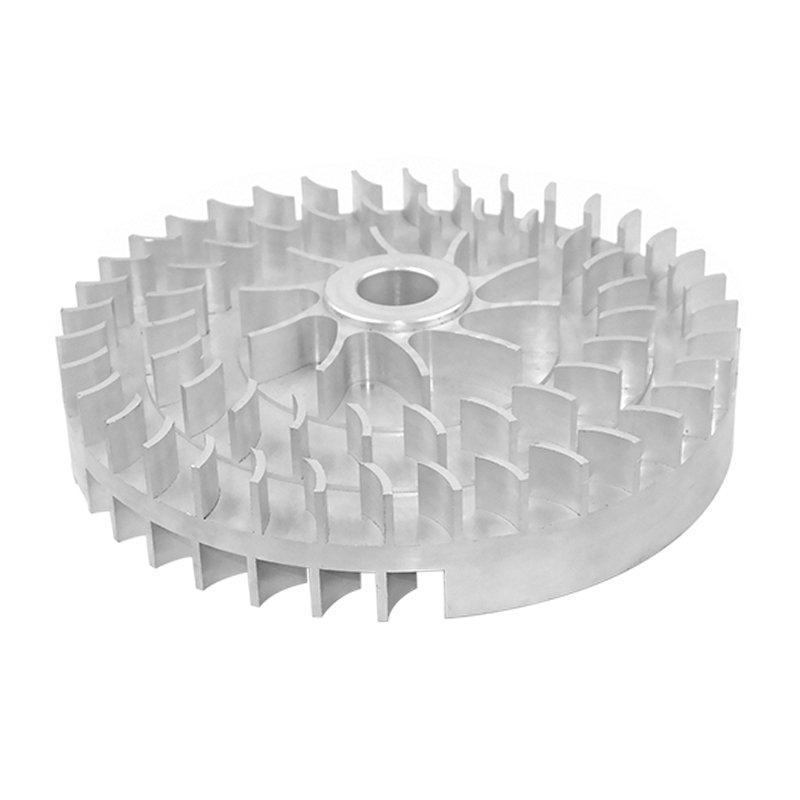

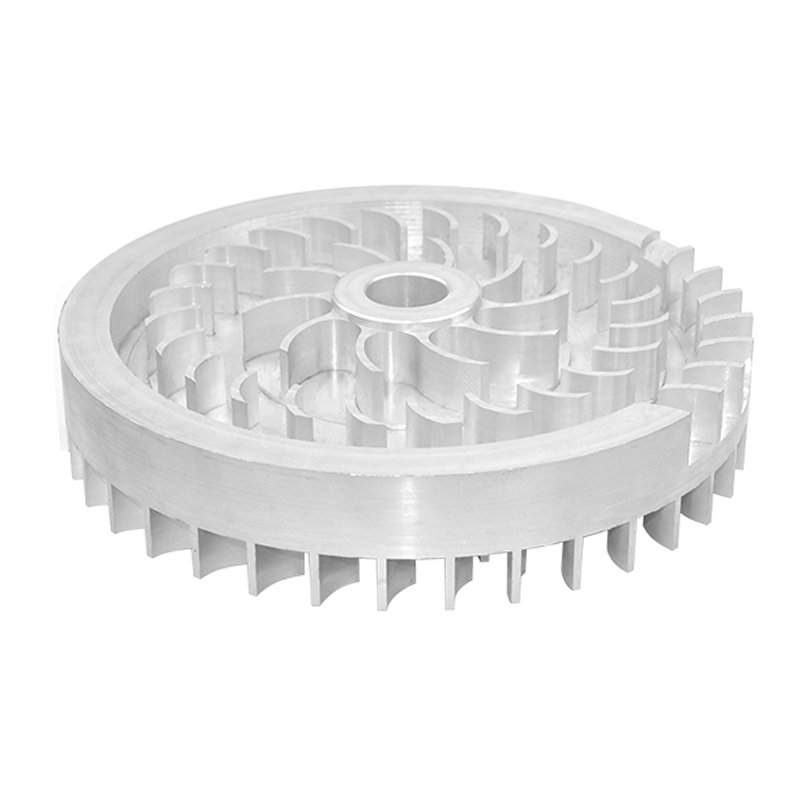

CNC Aluminum Flywheel shown above is a precision-engineered rotating mechanical component designed to store rotational energy and stabilize power output in systems with intermittent torque. Manufactured from high-strength aluminum alloy, this flywheel features an optimized finned structure that balances lightweight design, strength, and excellent heat dissipation.

Thanks to advanced CNC machining technology, this aluminum flywheel delivers outstanding dimensional accuracy, dynamic balance, and long service life—making it ideal for performance engines and energy management systems.

As an experienced OEM aluminum flywheel manufacturer, we supply custom and production-ready flywheels for automotive, motorsport, and industrial energy applications worldwide.

Material

Aluminum Alloy (6061 / 7075 optional)

Lightweight and high strength

Excellent thermal conductivity

Good fatigue resistance

Ideal for high-speed rotating applications

CNC Machining Processes Involved

This aluminum flywheel is produced using high-precision CNC machining to ensure consistent quality and performance:

CNC Turning – precision outer diameter, inner bore, and concentric alignment

CNC Milling – complex radial fin geometry for strength and heat dissipation

Precision Boring – accurate shaft or hub fitting

Dynamic Balancing – ensures vibration-free operation at high RPM

Deburring & Edge Finishing – enhances safety and part longevity

Optional Anodizing – improves corrosion resistance and surface hardness

These processes guarantee tight tolerances, structural integrity, and long service life.

Key Features & Advantages

Lightweight aluminum design reduces rotational inertia

Optimized fin structure improves heat dissipation

Enhances engine smoothness and torque consistency

High fatigue resistance for long-term operation

Excellent dimensional accuracy and balance

Suitable for high-speed and high-load environments

Applications & Use Cases

This CNC aluminum flywheel is widely used in:

Internal combustion engines (reciprocating engines)

Automotive and motorsport power systems

Small engines and performance machinery

Mechanical energy storage systems

Regenerative braking and hybrid system development

Industrial rotating equipment

Ideal for OEM manufacturers, automotive suppliers, and R&D engineers.

Custom Aluminum Flywheel Manufacturing (OEM / ODM)

We provide custom CNC aluminum flywheel manufacturing services, including:

Custom diameters, thicknesses, and bore sizes

Material options: 6061, 7075, or special aluminum alloys

High-speed dynamic balancing

Surface treatments: anodizing, polishing, bead blasting

Prototype to mass production support

Low MOQ and fast lead times available for B2B clients.

Why Choose Us as Your Aluminum Flywheel Supplier?

- Professional CNC machining factory

- OEM & ODM manufacturing capability

- Strict quality control and inspection

- Competitive pricing for bulk orders

- Global export experience for industrial parts

We help B2B buyers reduce cost, improve performance, and accelerate product development.

Reviews

There are no reviews yet.