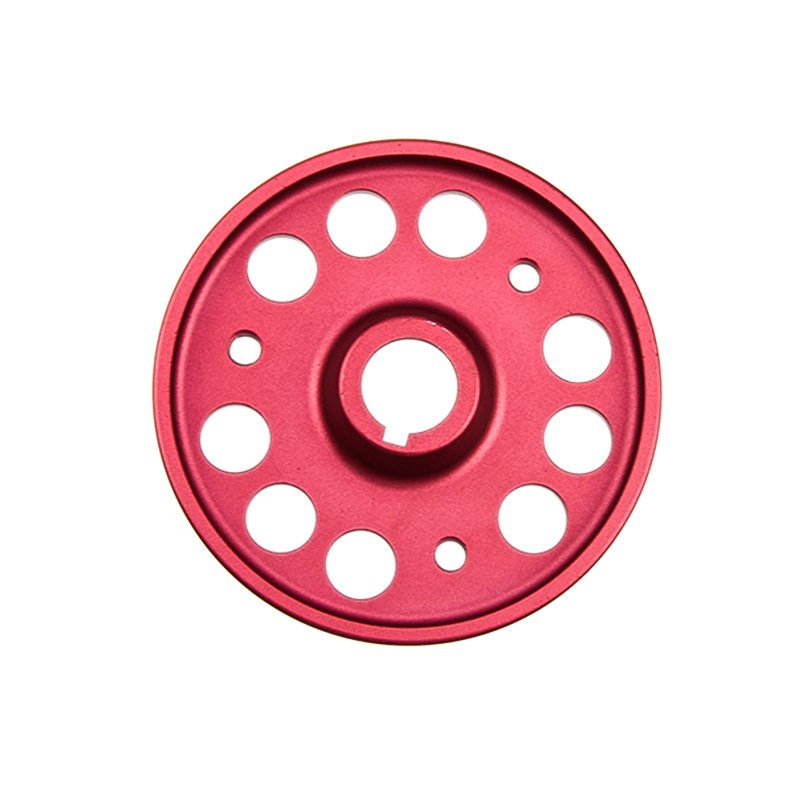

CNC Machined Aluminum Hub Adapter

Red Anodized Lightweight Mechanical Hub Connector

CNC Machined Aluminum Hub Adapter, designed as a precision mechanical interface for connecting components with different bolt patterns, diameters, or mounting standards. Its structure—featuring a central bore with keyway/slot, multiple evenly spaced peripheral bolt holes, and a lightweight hollowed design—indicates common use in racing steering wheel systems, performance automotive assemblies, industrial couplings, and standardized HUB mounting systems.

This type of adapter is also compatible with widely used standards such as 1.375×24 TPI HUB interfaces, making it suitable for applications where cross-brand compatibility and modular installation are required.

Material

Aluminum Alloy (6061-T6 / 7075-T6 optional)

High strength-to-weight ratio

Excellent corrosion and oxidation resistance

Ideal for motorsport and precision mechanical assemblies

Manufacturing & Machining Processes

This hub adapter is produced using high-precision CNC machining to ensure accuracy, concentricity, and long-term durability:

CNC Turning – forming the circular body, stepped profiles, and hub seat

CNC Milling – machining the keyway, slots, and weight-reduction pockets

Precision Drilling – evenly spaced peripheral bolt holes

Thread Tapping – internal or external threads (e.g., 1.375×24 TPI)

Deburring & Edge Chamfering – smooth, safe assembly surfaces

Anodizing (Red) – enhanced wear resistance and professional finish

Dimensional Inspection – ensuring tight tolerances and perfect alignment

Key Design Features

Central bore with keyway or locking slot for precise positioning

Multiple bolt holes for standardized mounting patterns

Lightweight perforated structure reduces rotational mass

High concentricity for smooth torque transmission

Red anodized surface improves corrosion resistance and aesthetics

Functional Advantages

Enables connection between components with different interfaces

Improves compatibility across multiple brands and systems

Reduces overall system weight without sacrificing strength

Ensures stable, vibration-resistant mechanical coupling

Application Range

This CNC aluminum hub adapter is widely used in:

Racing and performance steering wheel systems

Automotive and motorsport hub assemblies

Standardized HUB mounting systems (e.g., 1.375×24 TPI)

Industrial mechanical couplings and adapters

Custom CNC-machined mechanical interfaces

Surface Finish Options

Red anodizing (standard as shown)

Black, blue, or silver anodizing

Hard anodizing for high-wear environments

Sandblasted + anodized finish

Custom laser marking or logo engraving

Customization & OEM Services

Custom bolt patterns and hub standards

Different diameters, thicknesses, and keyway designs

Tight tolerance CNC machining

Small-batch prototyping to mass production

Why Choose Our CNC Hub Adapters

Precision CNC turning and milling

Lightweight yet high-strength aluminum construction

Excellent compatibility with standardized HUB systems

Professional anodized surface treatment

Full OEM & ODM customization support

If you are searching for CNC machined aluminum hub adapters, lightweight red anodized hub connectors, or precision HUB interface adapters, Customization this product delivers excellent strength, accuracy, and cross-platform compatibility for high-performance mechanical applications.

Reviews

There are no reviews yet.